Single-Ply Roofing for Your Building

TPO The Affordable Solution for Long-Lasting Protection

Single-Ply (TPO) Roofing in Brooksville & Spring Hill, FL

A Durable Flat & Low-Slope Roofing System Built for Florida Heat & Heavy Rain

If you have a flat or low-slope roof, a single-ply Thermoplastic polyolefin (TPO) roofing system is one of the most dependable ways to prevent leaks and reduce heat buildup in Brooksville and Spring Hill. JK Johns Roofing & Sheet Metal installs properly welded Thermoplastic polyolefin (TPO) systems designed for Florida weather—then we detail the edges, penetrations, and drainage so your roof performs long-term.

Why Single-Ply Thermoplastic polyolefin (TPO) Roofing Makes Sense for Flat & Low-Slope Roofs

If you’re comparing flat or low-slope roofing options, you’re probably trying to answer three questions: Will it stop leaks, will it hold up in Florida storms, and will it be worth the money long-term? Single-ply Thermoplastic polyolefin (TPO) is popular across the Greater Tampa Bay area because it uses heat-welded seams for strong waterproofing and is built to handle intense sun and heavy rain.

If you want to compare systems before you decide, review our Modified roofing and roof coatings options.

1. Leak Resistance (Welded Seams)

Thermoplastic polyolefin (TPO) seams are heat-welded, creating a strong bond that helps prevent the “seam leaks” many flat roofs struggle with.

2. Storm & Wind-Driven Rain Protection

For Florida weather, the details matter—edge metal, flashing, and penetrations. Done right, a Thermoplastic polyolefin (TPO) system is built for wind-driven rain and severe summer storms.

3. Energy Savings (Reflective Options)

White Thermoplastic polyolefin (TPO) membranes can reflect heat and reduce roof surface temperatures, which may help lower cooling demand in hot months.

4. Durability Against Sun & Heat

Thermoplastic polyolefin (TPO) is designed to resist ultraviolet (UV) exposure, thermal cycling, and surface cracking—common issues in long Florida summers.

5. Low Maintenance & Repairability

Most issues on low-slope roofs happen at drains, edges, or penetrations. Thermoplastic polyolefin (TPO) is typically straightforward to inspect and repair when maintained.

6. Great for Large Flat Areas

Thermoplastic polyolefin (TPO) is often a strong fit for commercial buildings, warehouses, and multi-unit properties because it installs efficiently over wide roof areas.

7. Options for Roof “Recover” in Some Cases

Depending on the existing roof condition, some buildings may qualify for an overlay (recover) instead of a full tear-off—an inspection determines what’s safe and code-compliant.

8. Long-Term Value & Warranty Readiness

A properly installed Thermoplastic polyolefin (TPO) system can deliver long service life—especially when paired with correct drainage, flashing, and documented inspections.

Want a straight answer on whether Thermoplastic polyolefin (TPO) is right for your building? Schedule a roof inspection and we’ll review drainage, seams, and flashing details.

Proudly serving Brooksville, Spring Hill, and Hernando County, plus the Greater Tampa Bay area including Tampa and St. Petersburg.

Why Choose JK Johns for TPO Roofing?

We’ve served Brooksville, Spring Hill, and Hernando County for decades. Our team focuses on the details that protect flat roofs long-term—proper slope/drainage planning, clean edge work, and careful sealing around penetrations.

Single-Ply Roofing Systems

The Answer To Low Slope and Flat Roofs

Single-Ply Thermoplastic polyolefin (TPO) Roofing Benefits for Flat & Low-Slope Roofs

Protect Your Property with Durable and Reliable Single-Ply Roofing

Affordability

Colors

Durability

Energy Efficiency

Improved Longevity

Resale Value

Single-Ply Roofing Colors

Your Choices Are Limited When It Comes To Single-Ply Roofing Material

The samples displayed below feature colors available when it comes to single-ply roofing.

White

Gray

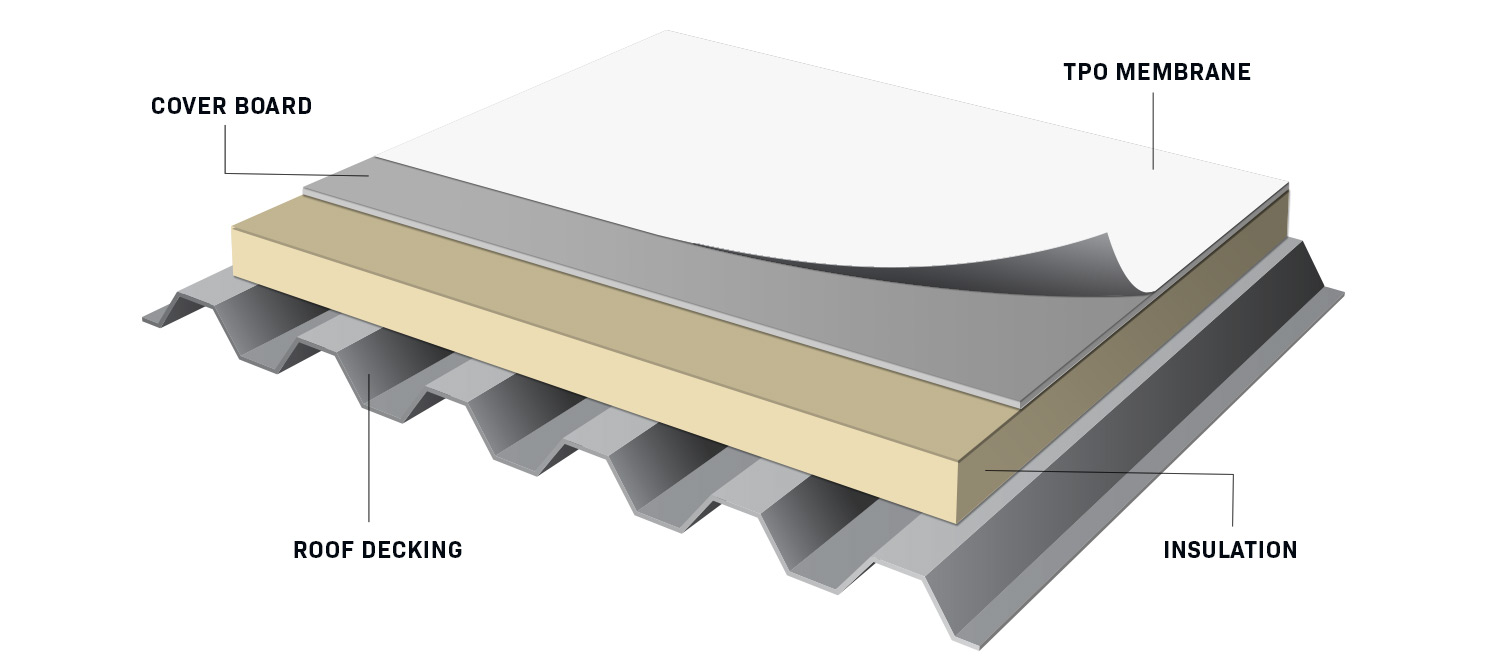

What Is Under My Single-Ply Roof?

What Lies Beneath Your Single-Ply TPO Roof?

A single-ply TPO roof is more than just its visible surface; it comprises several essential layers that contribute to its performance and durability. At the base, you’ll find the roof deck, which can be made from concrete, wood, or metal. This foundational layer provides structural support and stability for the entire roofing system. If you suspect trapped moisture or an active leak, start with a roof inspection so we can verify the roof deck, seams, and penetrations.

Above the deck, insulation is typically installed, with ISO board being a common choice. This insulation layer enhances energy efficiency by reducing heat transfer and promoting climate control within the building.

Next, a cover board may be added to provide additional protection and enhance the overall integrity of the roof. Finally, the TPO (Thermoplastic Olefin) membrane is installed, creating a seamless, durable barrier that resists UV rays and weathering. Together, these components form a robust system that protects your property while maximizing energy efficiency and longevity.

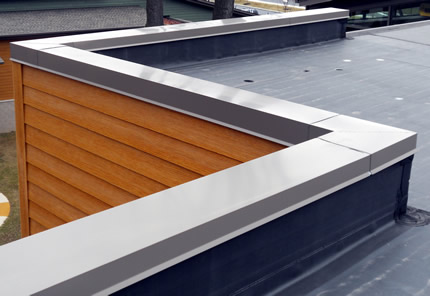

Do I Get New Trim Metals ?

Trim metals are vital elements of a single-ply roof system, offering both practical benefits and visual enhancement. These components, which include flashing, coping, and edge metal, serve essential roles in maintaining the integrity of your roofing structure. Flashing is strategically installed at critical points, such as seams and penetrations, to effectively redirect water away from vulnerable areas, preventing potential leaks that could compromise the roof’s performance. It acts as a barrier against moisture intrusion, helping to extend the lifespan of your roofing system. Coping provides a protective cap for parapet walls, shielding them from harsh weather conditions while adding an attractive finishing touch. It not only enhances the aesthetic appeal of the roof but also reinforces its durability by preventing water damage to the wall edges. Finally, edge metal is installed along the perimeter of the roof to ensure proper water drainage and provide a clean, finished look. Together, these trim metals significantly contribute to the functionality and longevity of a single-ply roof while enhancing its overall appearance.

The Role of Trim Metals in Your Single-Ply Roof System

Trim metals are essential components of a single-ply roof system, providing both functionality and aesthetic appeal. These metals, such as flashing, coping, and edge metal, play a crucial role in protecting your roof from water intrusion and ensuring long-lasting performance.

Flashing is used to redirect water away from critical areas, such as joints and penetrations, preventing leaks that can compromise the integrity of the roofing system. It is typically made from aluminum, copper, or galvanized steel for durability.

Coping serves as a protective cap for parapet walls, shielding the edges from weather damage and enhancing the roof’s overall appearance. Like flashing, coping is available in various materials to match your building’s style.

Edge metal, often installed at the perimeter of the roof, provides a clean finish while ensuring proper water drainage. Together, these trim metals reinforce the effectiveness of a single-ply roof while adding an attractive finishing touch.

Because trim metals are such a common leak point on low-slope roofs, our custom sheet metal fabrication helps ensure better fit, stronger edges, and cleaner long-term performance.

A Look at Some Eye-Catching Single-Ply Roofs

See more completed projects in our Image Gallery.

Examining sample photos of single-ply TPO roofing is an excellent way for homeowners to envision how different colors and finishes will complement their home’s exterior. These visual references allow individuals to see the impact that specific TPO membrane hues can have on overall curb appeal and design aesthetics. By exploring a variety of images showcasing different architectural styles and color combinations, homeowners can better understand how various shades—ranging from classic whites and grays to vibrant greens and blues—interact with other elements such as siding, trim, and landscaping.

This exploration not only aids in making informed decisions but also inspires creativity when selecting a roofing option that aligns with personal style and the overall look of the home. Ultimately, viewing sample photos serves as a valuable tool in the roofing selection process, ensuring that the final choice enhances the property’s beauty while providing lasting quality and durability associated with single-ply TPO roofing systems.

Affordable Roofing Financing in Brooksville & Spring Hill

At JK Johns Roofing & Sheet Metal, we believe a safe roof shouldn’t be a financial burden. We offer flexible roofing financing options and low monthly payment plans for homeowners in Hernando County and the surrounding Tampa Bay area, making it easier than ever to invest in a high-quality shingle or metal roofing system.

Words From Our Customers

We pride ourselves on delivering exceptional service and high-quality results to our valued customers. One of the most rewarding aspects of our work is receiving heartfelt testimonials from our happy customers. These testimonials not only validate our efforts but also inspire us to continuously improve and serve our community better. We are incredibly grateful for the feedback we receive. Here are just a few excerpts from recent testimonials that highlight the satisfaction of our customers.

Are You Ready For Our Roofing Services

Single-Ply (TPO) Roofing FAQs for Brooksville & Spring Hill

Below Are A Few Frequently Asked Questions.

Single-ply Thermoplastic olefin (TPO) roofing is a durable membrane system used on flat and low-slope roofs. It’s heat-welded at seams to form a watertight surface, and it’s popular in Florida because it performs well in intense sun and heavy rain.

It can be—when the roof has proper drainage and the system is installed correctly. Low-slope roofs should be evaluated for slope, drain locations, and areas where water sits. We look for weak points early so they can be corrected before leaks become recurring problems.

Many single-ply systems last 20–30 years depending on installation quality, roof traffic, drainage, and maintenance. Regular inspections (especially after major storms) help extend lifespan and catch seam or flashing issues early.

Sometimes, yes—if the existing roof and deck are sound and the system design allows it. A roof inspection determines whether a recover is appropriate or if a full tear-off is the safer long-term choice.

Often, yes. Perimeter edge metal, wall flashings, and penetrations are common leak points on low-slope roofs. Updating trim metals and flashing details is one of the best ways to improve waterproofing and overall system performance.